Project-based special solutions for the defence industry

Over the past 10 years, we have continuously developed industry-specific production capabilities, such as those for the medical and defense industries. We produce solutions both as series as well as project-based tailor-made solutions.

We own the AQAP 2110:2016 certificate and the readiness to meet special requirements specific to the defence industry

Producing special solutions

We use the PROTODUCTION service to produce project-based special solutions in the field of defence.

Toci’s Protoduction service makes it possible to establish the challenges, design and prototype a solution and then produce it in series within a short period of time.

We developed a new type of flexible and durable weapon bracket for firearms, which have been used in several foreign missions, we produced metal structures and parts for the conversion of CV90 combat vehicles of the Estonian Defence Forces, and we built diagnostic rooms for mobile computer tomography for defence forces in Europe.

Our most ordered products include new types of weapon brackets used in various vehicles, special-purpose container solutions, superstructures for trucks and trailers, a stainless furniture range, etc.

Project-based special solutions

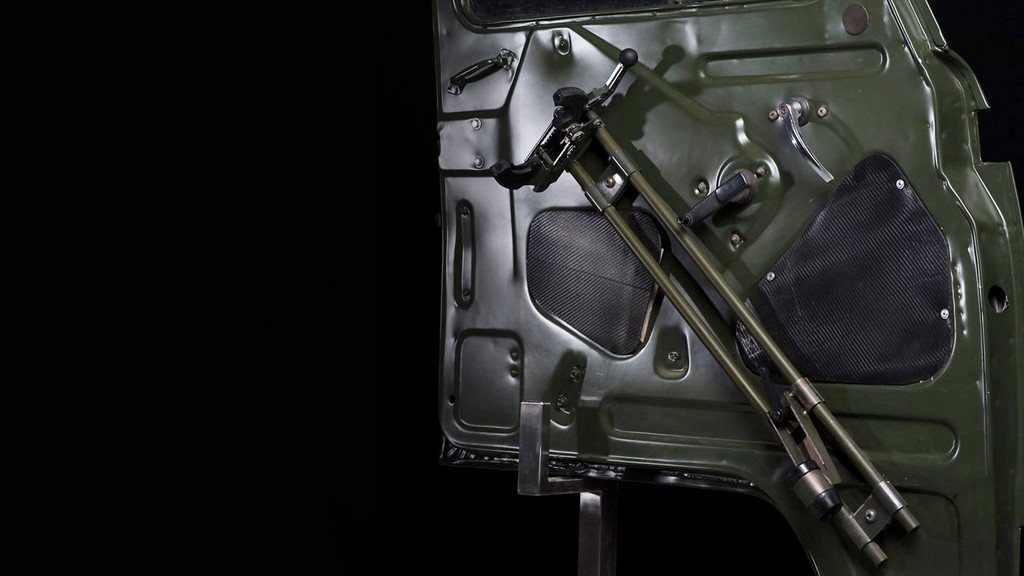

New type of weapon brackets

PROJECT OVERVIEW

Originally developed in cooperation with the Norwegian Armed Forces, a new type of universal weapon bracket solution for mounting new and old types of firearms in armoured and non-armoured vehicles, heavy equipment, and ships

REQUIREMENTS

The design had to take the ease of use and functionality of the device to a whole new level, to safely and easily attach firearms to the frame with a movable front and rear mount

DURATION

A little over a year

engineering

laser cutting

metal works

CNS turning

CNC milling

refinement

final assembly

testing

bending

welding

Read more

laser cutting

welding

metal works

CNC turning and milling

bending

refinement

final assembly

Metal structures with details for the conversion of CV90 combat vehicles of the Estonian Defence Forces

PROJECT OVERVIEW

Ordering, delivery, and production of black, stainless steel, and aluminium metal assemblies and parts necessary for the conversion of CV90 combat vehicles

REQUIREMENTS

Supply of appropriate metal assemblies and parts for the conversion of infantry vehicles so that combat vehicles can fulfil nine different modifications

DURATION

Two years